Pre Engineered Steel Buildings (PEB) Memaar Building Systems

A PEB building, as it is called, is engineered at a factory and assembled at site. Built-up sections are fabricated at the factory to size and then transported to site to assemble with bolted connections. This type of Structural Concept is generally used to build Industrial Buildings, Metro Stations, Canopies, and Warehouses etc.

PEB interior Pre engineered buildings, Shed design, Industrial sheds

Pre-engineered building (PEB) has greater advantages in long-span structures. In this paper, pre-engineered industrial building of 30 mspan and 10 m eave height with slope of 10° has analyzed and designed using staad pro to understand the behavior of structure and to achieve the economy in steel design by reducing the material quantity as well as number of purlins and saving in erection time.

Pre Engineered PEB Concept Banu Mukhtar

Pre Engineered Buildings (PEB) are the buildings which are engineered at a factory and assembled at site. Usually PEBs are steel structures. Built-up sections are fabricated at the factory to exact size, transported to site and assembled at site with bolted connections.

Peb Building at Rs 5000/feet Prefabricated Buildings ID 2900788012

Design of Pre Engineered Building (PEB) system is Computer assistant. And design to create a building for specific use like, • Ware houses • Factories • Workshops • Offices • Gas stations • Vehicle parking sheds • Show rooms • Aircraft hangers • Sports Stadiums. This complete building system is Pre Engineered to make a easy production.

Overview of PreEngineered Buildings & Types of PEB

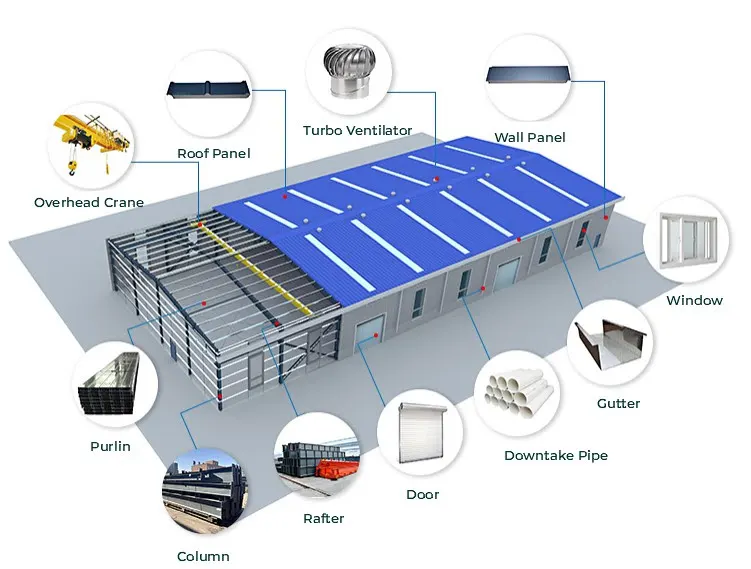

A pre-engineered building is a system utilizing three distinct product categories: Built-up "I" to shape primary structural framing members (columns and rafters) Cold-formed "Z" and "C" to shape secondary structural members (roof purlins, wall girts, and eave struts) Roll-formed sheeting profiles (roof and wall cladding).

PEB Manufacturing in Surat Faith PEB

Nowadays, pre-engineered building (PEB) structures are getting very popular globally. These type of structures are manufactured in factory and erected on site. Also, these structures are economical, eco-friendly and recyclable. PEB heavy structures need advanced software like SAP2000 for analysis and design.

peb structure design drawing donovanbelliveau

In structural engineering, a pre-engineered building ( PEB) is designed by a PEB supplier or PEB manufacturer with a single design to be fabricated using various materials and methods to satisfy a wide range of structural and aesthetic design requirements.

An Overview of Foundation Design for PEB Steel Buildings

From the parametric study, the PEB is fabricated in a factory and then it is erected at site as per the requirement. Keywords Steel design ·Moment reaction ·Staad pro 1 Introduction Pre-engineered building came into existence in 1960. Pebs are used for making construction materials in a variety of shapes. This type of construction is usually

PEB Building at Rs 300/square feet pre engineered building, प्रीफेब्रिकेटेड बिल्डिंग

The purpose of this manual is to provide building officials, design and construction professionals, and the general public with a summary and guide to key elements of the statutes, regulations, and policies governing the construction industry in the state of Nevada. The regulatory bodies responsible for assembling this manual protect the public.

PEB Metal Buildings Customized Design Easy Construction Erection For Oil & Gas Industry

The structure is proposed as a Pre-Engineered Building of. 79.3 meters width, 10 bays each of 8.48 meters length and an eave height of 22meters. In this study, a PEB frame of 22 meter width is taken into account and the design is carried out by considering wind load as the critical load for the structure.

PEB Shed Structures, Prefabricated Industrial Structures, Primary Framing System, प्री

Pre Engineered building (PEB) is a revolution in building storage capacity structures. A structural frame built completely with steel with a standard roof and standard walls. The structure is built completely at the factory and brought to the site to be installed using cranes.

Home Supreme PEB

In the field of structural engineering, a pre-engineered building or (PEB) is designed by a PEB supplier or a PEB manufacturer that has a single design and that is fabricated using various materials and methods that can satisfy different types of structural and aesthetic design requirements.

PreEngineered Buildings Manufacturer in India, Advantages PEB Structure Manufacturer in India

A pre-engineered steel building is a modern technology where the complete designing is done at the factory and the building components are brought to the site in CKD (completely knock down condition) and then fixed/jointed at the site and raised with the help of cranes.

Meridian PEB Buildings

Detailing for Haunch Planning of the PEB buildings (low rise metal buildings and arranging different building components is a very important step for the designer before proceeding with the design.

PVC PEB Metal PEB Structure, Rs 230 /square feet Peb Metal Buildings Private Limited ID

What Are Pre-Engineered (Prefabricated) Metal Buildings (PEMBs)? Pre-engineered metal buildings (PEMBs) are structures made from prefabricated parts that are assembled on site. PEMBs first became popular in the 1930s, when they were used for things like airplane hangars and grain storage facilities.

a large building under construction with lots of steel beams on it's roof and walls

Pre-Engineered Buildings (PEB) are steel structures whose primary components are pre-fabricated in the factory and then shipped to the site; assembled using bolting and fastenings. In general, PEB has tapered rigid columns and rafters which are built-up welded sections and are joined or linked through connection plates using high-strength bolts.